Description

Liquid Filling Machine

Working principle

A fluidic container imbuing apparatus is a specialized machine crafted to imbue a diverse range of liquid products into containers. This highly automated device seamlessly processes water, juice, oil, vinegar, sauces, and various other beverages with ease.

The fluidic container imbuing apparatus comprises a state-of-the-art conveyor belt, which transports containers to the filling station, a high-tech nozzle or nozzles that accurately dispenses liquid into the containers, and an advanced capping or sealing station that caps or seals the filled containers. This machine can be precisely calibrated to accommodate varying container sizes and shapes while filling containers at an impressive speed.

Workflow

The machine typically functions in the following manner:

1.Pre-Production: Prior to bottling, the skilled operator must meticulously fine-tune the machinery to ensure seamless operation and impeccable accuracy. This includes intricately adjusting the height of the filling nozzle and programming the desired fill level to perfectly match the specific product and bottle dimensions.

2.Bottle feeding: Empty bottles are placed onto a conveyor belt that moves them to the filling station. Some machines may also have an automatic bottle sorting and feeding system.

3.Filling: Once the bottles reach the filling station, the filling nozzle or nozzles dispense the liquid into the bottles. The liquid is measured and controlled to ensure accurate and consistent filling levels.

4.Capping or sealing: After the bottles are filled, they are moved to a capping or sealing station, where caps or seals are applied to the bottles. This may be done using automated equipment, such as capping heads or sealing rollers.

5.Labeling and packaging: Once the bottles are filled and sealed, they may be labeled, packaged, and prepared for shipment.

Filling accuracy

The seamless operation of liquid bottle filling machines hinges on their filling accuracy. With advanced sensors and control systems now commonplace, these machines are primed to deliver pinpoint precision. Accurately measured in relation to target fill volume, the filling machine’s effectiveness can be influenced by variables such as the liquid’s viscosity, the speed of the machine, and the type of nozzle employed.

Features

Like snowflakes, each liquid bottle filling machine is unique, with a dazzling array of features that set them apart from one another. But amidst this variety, certain common features shimmer like diamonds, representing the gold standard in bottle-filling technology:

1.Precise volume control: This machine boasts an extraordinary volume control system, providing unparalleled precision and repeatability in filling bottles with exacting volumes of liquid. With this advanced feature, you can reduce waste and boost efficiency to unprecedented levels.

2.High-speed operation: Lightning-fast and accurate, these machines fill bottles with rapid efficiency, ensuring products hit the market at lightning speed and meet even the most demanding production schedules with ease.

3.Versatile filling capabilities: FWith the prowess to handle liquids ranging from feather-light viscosity to thick, syrupy gels, these machines boast an extraordinary range of filling capabilities that are unmatched in the industry.

4.Modular design: Swap, repair, upgrade with ease for ultimate flexibility and durability.

5.User-friendly controls: From touchscreen interfaces to push-button systems, these machines offer simple operation, making them accessible for operators of all skill levels.

6.Durable build: Crafted from top-notch materials, these machines can handle relentless use and require little maintenance, ensuring long-lasting performance.

7.Eco-friendly technology: These machines incorporate energy-saving features like automatic shut-off, low-power consumption modes, and other innovative technologies to cut down on energy costs and reduce their carbon footprint.

In essence, liquid bottle filling machines are a boon for manufacturers seeking to optimize their production workflows and enhance the quality of their products. By offering swift, seamless, and precise filling of various liquid products into bottles, these machines enable manufacturers to take their production capabilities to the next level.

Maintenance

Maintaining a liquid bottle filling machine is essential to ensure its longevity, minimize downtime, and prevent any potential hazards. Here are some creative ways to approach maintenance:

1.A Clean Sweep: A clean machine is a happy machine. Schedule regular cleaning sessions to wipe down the machine’s surfaces and components, removing any residue or contaminants that may have built up during the production process.

2.Proactive Maintenance: Prevent problems before they occur with proactive maintenance. Create a schedule for regular inspections, lubrication, and part replacement to avoid unexpected downtime and costly repairs.

3.Automation: Automate maintenance by incorporating sensors that detect part replacement needs or software that tracks usage and notifies maintenance staff of routine service requirements.

4.Safety First: Don’t overlook safety in your maintenance plan. Train personnel on proper lockout/tag-out procedures, so they can safely access the machine for maintenance or repair work.

By implementing these creative maintenance strategies, you can keep your liquid bottle filling machine running smoothly and efficiently, ensuring the quality and safety of your products and maximizing your production output.

Technical Parameters

Model | LFL-2H | LFL-4H | LFL-6H | LFL-8H | LFL-12H |

Filler head | 2 head | 4 head | 6 head | 8 head | 12 head |

Speed | 5-20 b/min | 10-20 b/min | 10-30 b/min | 15-40 b/min | 30-80 b/min |

Range | 10-100ml 30-300ml 50-500ml 100-1000ml 300-2500ml 1000-5000ml | 10-100ml 30-300ml 50-500ml 100-1000ml 300-2500ml 1000-5000ml | 10-100ml 30-300ml 50-500ml 100-1000ml 300-2500ml 1000-5000ml | 10-100ml 30-300ml 50-500ml 100-1000ml 300-2500ml 1000-5000ml | 10-100ml 30-300ml 50-500ml 100-1000ml 300-2500ml 1000-5000ml |

Error | Within 0.5g (when 500ml) | Within 0.5g (when 500ml) | Within 0.5g (when 500ml) | Within 0.5g (when 500ml) | Within 0.5g (when 500ml) |

Voltage | 220v/380v 50-60hz | 220v/380v 50-60hz | 220v/380v 50-60hz | 220v/380v 50-60hz | 220v/380v 50-60hz |

Air pressure | 0.5-0.6Mpa | 0.5-0.6Mpa | 0.6-1Mpa | 0.6-1Mpa | 0.6-1Mpa |

Weight | 300kg | 350kg | 350kg | 400kg | 450kg |

Dimention | 2000x900x1800 mm | 2500x900x2200 mm | 2500x900x2200 mm | 2500x900x2200 mm | 2500x900x2200 mm |

Grain Filling Machine

Working principle

The working principle of a linear weigher involves a series of weighing hoppers that are filled with product from a supply hopper, and each hopper is equipped with a load cell and a discharge gate. Here are the steps involved in the operation of a typical linear weigher:

1.Product supply: The product to be weighed is supplied to the linear weigher via a feeding system, such as a vibrating feeder, conveyor belt or bucket elevator. The product flows into the top of the supply hopper.

2.Product distribution: Once the product is in the supply hopper, it is distributed evenly to each weighing hopper. This is achieved using a series of chutes and gates, which are opened and closed sequentially to allow the product to flow into each hopper.

3.Weighing: As the product is being distributed to each weighing hopper, the load cells underneath each hopper measure the weight of the product in real time. The load cell sends a signal to the controller, which uses this information to calculate the amount of product in each hopper.

4.Optimizing precision: Through intuitive adjustments, the controller sensitively regulates the aperture of every discharge gate, precisely matching the weight of each product in its corresponding hopper. Such intricate fine-tuning guarantees that each hopper dispenses with meticulous accuracy, ultimately resulting in the desired aggregate weight of the product.

5.Product Release: When the gates have been precisely calibrated, the product is released from each hopper onto a collection conveyor or packaging machine. The release gates are opened in unison to ensure the simultaneous dispensing of the product.

The linear weigher system is meticulously orchestrated by a cutting-edge computerized controller, guaranteeing unparalleled precision and reliability throughout the entire automated process. Widely employed in the food industry to package an array of products, such as delectable snacks, crisp cereals, flavorful nuts, nourishing pet food, and other free-flowing dry goods, linear weighers are an indispensable tool for achieving optimal productivity and quality.

Feature

Behold the wonders of the linear weigher! Equipped with high-precision load cells, this marvel of engineering guarantees pinpoint accuracy and consistency in dispensing every product. Need speed? Fear not, for the linear weigher can handle the high demands of any production line with its lightning-fast operation. Versatile and flexible, it can adapt to a vast range of products – from powders to small parts – and can even adjust to accommodate different shapes and sizes. With its user-friendly interface, even the technologically challenged can easily operate this machine with minimal hassle. And let’s not forget about hygiene – the linear weigher boasts easy-to-clean surfaces and no exposed moving parts, ensuring optimal cleanliness and efficiency. Durability is also a non-issue – built with high-quality components and robust construction, the linear weigher can withstand the test of time and provide dependable operation. And lastly, the linear weigher seamlessly integrates with other equipment, forming a complete production line that’s guaranteed to make every product weighing a breeze.

Maintenance

Proper maintenance is important for ensuring the continued accuracy and reliability of a linear weigher. Regular cleaning, calibration, and inspection of the weighing hoppers, load cells, and other components can help to prevent downtime and ensure accurate weighing.

Technical Parameters for semi automatic filler

Model | Weight Range | Error | Speed (pcs/min) | Power | Weight | Dimension (mm) |

DCS-1H 1 head | 10-2000g 100-5000g 1-10kg 1-15kg 5-20kg | ±1% | 5-20 | 800W | 110kg | 700x700x1800 |

DCS-2H 2 head | 10-1000g 10-2000g 100-5000g | ±0.9% | 10-30 | 900W | 150kg | 700x900x1800 |

DCS-4H 4 head | 10-500g 10-1000g 100-2500g 200-5000g | ±0.8% | 20-50 | 1.2kw | 220kg | 900x1200x1900 |

A10 10 head | 10-2000g | ±0.1-1.5g | 50-80 | 3kw | 350kg | 1482x1080x1116 |

A14 14 head | 10-1000g | ±0.1-1.5g | 70-130 | 3.6kw | 400kg | 1700x1100x1265 |

Technical Parameters for auto filler

Model | Weigher | Circle | Range | Error | Speed (pcs/min) | Power | Weight (kg) | Dimension (mm) |

DCSL-1H | 1 | 1 bottle | 10-100g 50-500g 100-1000g 200-2000g 500-5000g | ±2g | 10-30 | 220V 2kw | 250 | 2000x900x1890 |

DCSL-2H | 2 | 1 bottle 2 bottle | 10-100g 50-500g 100-1000g 200-2000g | ±2g | 10-40 | 220V 2.5kw | 300 | 2000x900x1890 |

DCSL-4H | 4 | 1 bottle 2 bottle 4 bottle | 10-100g 50-500g 100-1000g | ±2g | 10-40 | 220V 3.3kw | 350 | 2000x900x1890 |

DCSL-10H | 10 | 1 bottle | 10-100g 50-500g 100-1000g | ±2g | 20-60 | 220V 3.3kw | 400 | 2000x900x1890 |

Powder Filling Machine

Working principle

An auger filler accurately measures and dispenses product into containers using a rotating screw.

1.Product is placed in a hopper: Load your product into the hopper, and let the auger filler machine take care of the rest with its consistent product flow.

2.The auger rotates: The motorized auger swiftly spirals inside the tube, snatching up product from the hopper and transporting it towards the filling nozzle.

3.Product is filled: The auger speed, pitch, and nozzle size control the volume of product dispensed into the container as it reaches the filling nozzle.

4.The container is filled: As the auger turns, the container is packed with product until it reaches the desired level. Then, the nozzle retreats and the container is primed for capping or sealing.

5.Repeat the process: The process is repeated for each container, and the auger is adjusted as needed to maintain the desired fill level and flow rate.

The specific working principle of an auger filler may vary depending on the type of machine used, such as single or multiple-head auger fillers, horizontal or vertical fillers, or volumetric or gravimetric fillers. However, the basic process of product loading, auger rotation, product dispensing, container filling, and adjustment is common to most auger filling machines.

Workflow

The machine works like this:

1.Preparation: Set up and calibration are essential before filling containers with powder. The operator must adjust the filling nozzle height and set the fill level according to the product and container size.

2.Powder feeding: The powder is fed into a hopper or holding tank that is located above the filling station. The hopper can be filled manually or automatically, depending on the machine’s design.

3.Filling: Once the containers reach the filling station, the filling nozzle or nozzles dispense the powder into the containers. The powder is measured and controlled to ensure accurate and consistent filling levels.

4.Leveling or settling: After the powder is dispensed into the container, the container may be gently tapped or vibrated to ensure that the powder settles and is evenly distributed in the container.

5.Capping or sealing: After the containers are filled, they may be moved to a capping or sealing station, where caps or seals are applied to the containers.

6.Labeling and packaging: Once the containers are filled and sealed, they may be labeled, packaged, and prepared for shipment.

The specific working principle of the powder filling machine may vary depending on the type of machine used, such as auger fillers, volumetric fillers, or net weight fillers. However, the basic process of powder feeding, filling, leveling or settling, capping or sealing, and labeling is common to most powder filling machines.

Feature

The features of an auger filling machine include:

1.Precision: Auger filling machines offer precise and meticulous dispensing of powdered or granular materials, ensuring consistently accurate filling weights or volumes. Their auger screw design enables them to dispense the exact amount of material required, making them an excellent choice for products that demand exact measurement.

2.Versatility: With the ability to fill a vast range of products, including powders, granules, and other free-flowing materials, auger filling machines are versatile machines that cater to a diverse range of industries. Whether it’s food, pharmaceuticals, chemicals, or cosmetics, these machines are fit for any application.

3.User-friendliness: Operating auger filling machines is a breeze, with their adjustable settings accommodating various container sizes and fill volumes. These machines are easy to clean and maintain, further adding to their ease of use.

4.Personalization: Auger filling machines offer a customizable experience that caters to unique production needs or preferences, showcasing their exceptional adaptability. They seamlessly integrate with other packaging equipment and can be modified to cater to specific applications, allowing for an unmatched level of flexibility.

5.Velocity: Auger filling machines exhibit exceptional filling speed, rendering them perfect for high-capacity production cycles. They can be fitted with numerous filling heads to accelerate the filling process.

6.Resilience: Auger filling machines boast robust construction with premium-grade materials, rendering them impervious to the rigors of demanding production settings and incessant operation, ultimately delivering unparalleled longevity.

Volumetric vs. gravimetric filling

Auger fillers can be designed to fill containers either by volume or by weight. Volumetric fillers measure the product based on the volume of the auger, while gravimetric fillers weigh the product as it is dispensed. Gravimetric fillers are typically more accurate but can be slower than volumetric fillers.

Maintenance

Auger fillers require regular maintenance to ensure they operate efficiently and accurately. Maintenance tasks may include cleaning, lubrication, inspection of wear parts, and calibration. Regular maintenance can also help prevent downtime and extend the life of the machine.

Technical Parameters

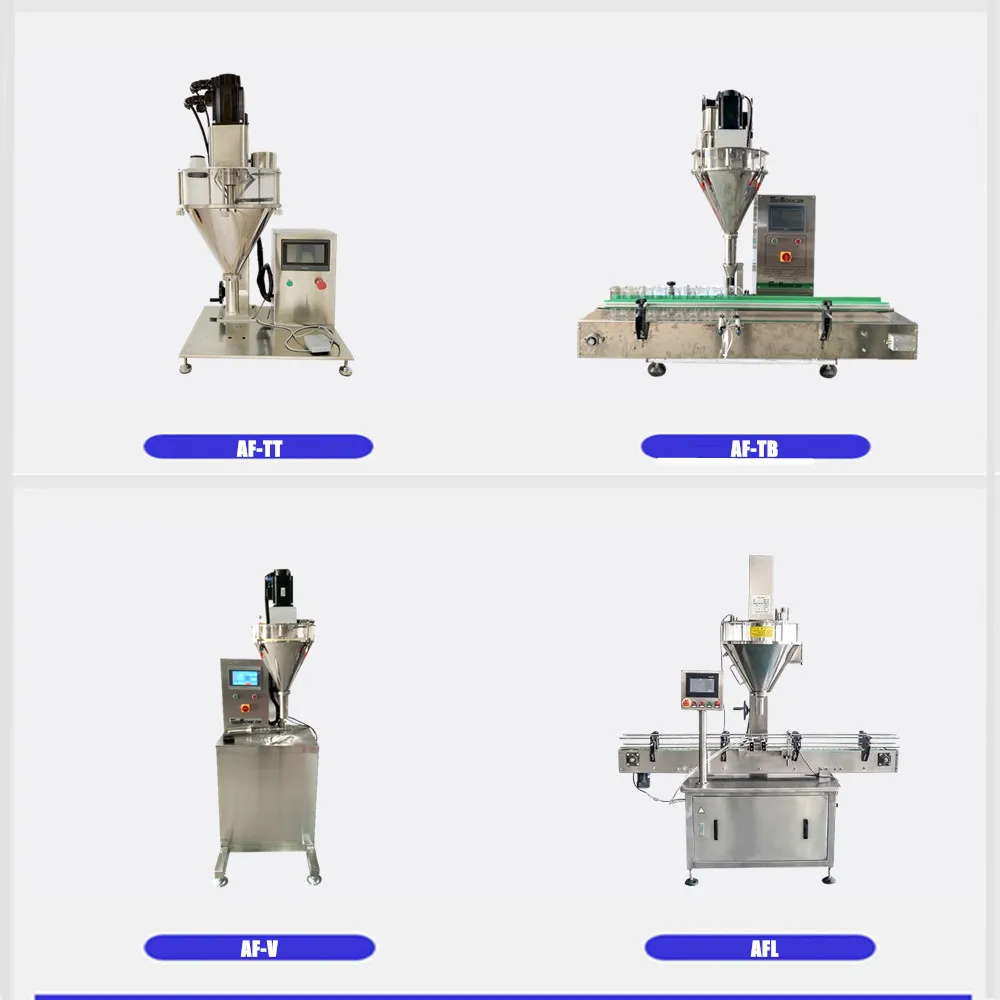

Model | AF-TT | AF-TB | AF-V | AFL |

Type | Table top | Table top + belt | Vertical | vertical + belt |

Range | 1-10g 5-25g 10-100g 25-150g 50-300g 100g-500g 200-1000g | 1-10g 5-25g 10-100g 25-150g 50-300g | 1-50g 10-200g 50-1000g 100-5000g | 1-50g 10-200g 50-1000g 100-5000g |

Speed | 20-50 pcs/min | 20-40 pcs/min | 20-50 pcs/min | 20-40 pcs/min |

Weight | 120kg | 200kg | 250kg | 300kg |

Dimension | 610x500x1200mm | 1600x700x1200mm | 950x700x1550mm | 1600x700x1600mm |

Reviews

There are no reviews yet.