Description

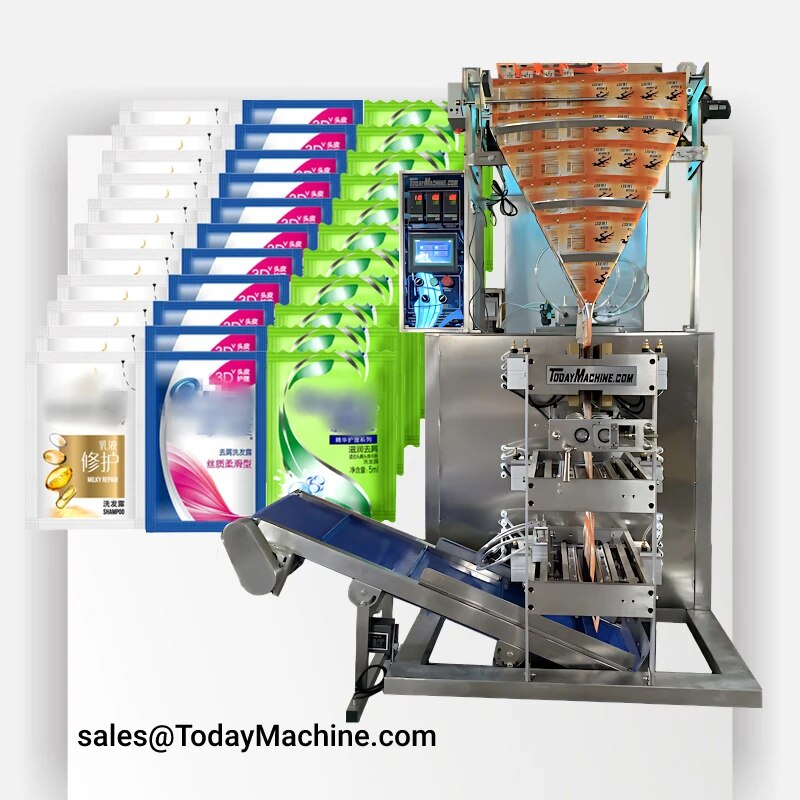

MULTI LANE PACKAGING MACHINE

A multi-lane liquid form fill seal machine that operates by film roll is a packaging machine that is used to automatically form, fill, and seal pouches or sachets from a continuous film roll.

The film roll is unwound and formed into a tube shape, which is then filled with liquid product through a filling nozzle. The pouch is then sealed on both ends, creating a complete package. The machine can produce several pouches simultaneously, increasing production speed and efficiency.

multi lane sachet packaging machine

High-speed production: Multi-lane machines can form, fill, and seal several pouches simultaneously, increasing production speed and efficiency.

Accurate filling: These machines are designed to provide consistent and accurate filling of pouches to ensure product quality and safety.

Versatility: These machines are suitable for filling and sealing a wide range of liquid products, including beverages, dairy products, and chemical solutions.

Compact design: Multi-lane machines have a compact design that saves space on the production floor.

INDUSTRIES AND APPLICATIONS

1.Food and Beverage Industry: These machines are used for packaging liquid products such as sauces, ketchup, mayonnaise, salad dressings, juices, energy drinks, and water.

2.Pharmaceutical Industry: These machines are used for packaging liquid products such as syrups, cough medicines, and other liquid medicines.

3.Cosmetic Industry: These machines are used for packaging liquid products such as shampoos, conditioners, lotions, and gels.

4.Chemical Industry: These machines are used for packaging liquid products such as detergents, cleaning solutions, and chemicals used in industrial processes.

5.Personal Care Industry: These machines are used for packaging liquid products such as hand sanitizers, mouthwash, and other personal care products.

Model | VFFS-M2 | VFFS-M3 | VFFS-M4 | VFFS-M5 | VFFS-M6 |

Lane | 2 | 3 | 4 | 5 | 6 |

Max film width (mm) | 320 420 500 600 | 320 420 500 600 | 320 420 500 600 | 320 420 500 600 | 320 420 500 600 |

Bag type | 4 side seal | 4 side seal | 4 side seal | 4 side seal | 4 side seal |

Bag size (mm) | L: 30-150/250 | L: 30-150/250 | L: 30-150/250 | L: 30-150/250 | L: 30-150/250 |

Range | 1-10ml 10-100ml 100-200ml | 1-10ml 10-100ml 100-200ml | 1-10ml 10-100ml 100-200ml | 1-10ml 10-100ml 100-200ml | 1-10ml 10-100ml 100-200ml |

Speed | 60-90 bag/min | 90-130 bag/min | 120-180 bag/min | 150-220 bag/min | 180-270 bag/min |

Power | 2kw | 2.5kw | 3kw | 3kw | 3kw |

Power supply | 220V 50Hz/110V 60Hz | 220V 50Hz/110V 60Hz | 220V 50Hz/110V 60Hz | 220V 50Hz/110V 60Hz | 220V 50Hz/110V 60Hz |

Dimension | 990x1150x1800mm | 990x1150x1800mm | 990x1250x1800mm | 990x1250x1800mm | 990x1250x1800mm |

Weight | 350kg | 400kg | 420kg | 420kg | 450kg |

Granule Packing Machine

GRANULE PACKING MACHINE WITH VOLUMETRIC CUP FILLER

A granule packing machine with a volumetric cup filler is a type of packaging machine that is used to package granular or powdered products such as sugar, salt, coffee, and spices. The volumetric cup filler is a key component of this machine, which is designed to measure a specific volume of product and dispense it into the packaging material.

The volumetric cup filler consists of a cup or scoop that is sized to measure a specific volume of product. The cup is attached to a conveyor system that moves it along the filling line. As the cup moves along the line, it passes through a product dispenser that fills the cup with the correct amount of product. Once the cup is filled, it is released into the packaging material, which is then sealed to create a finished product package.

Accurate and consistent filling: The volumetric cup filler accurately measures and dispenses a precise volume of product, ensuring that each package contains the same amount of product.

Speed: These machines are available in different sizes and configurations, ranging from low-volume to high-speed production lines capable of packaging thousands of products per hour.

Easy to operate: Granule packing machines with volumetric cup fillers are user-friendly and require minimal training to operate.

Durable: These machines are typically made of high-quality materials, making them durable and long-lasting.

INDUSTRIES AND APPLICATIONS

1.Food and beverage industry: These machines are commonly used in the food and beverage industry to package granular or powdered products such as sugar, salt, coffee, and spices.

2.Pharmaceutical industry: Used in the pharmaceutical industry to package granular or powdered medications.

3.Cosmetics industry: Used in the cosmetics industry to package powders such as talcum powder, face powders, and other similar products.

4.Chemical industry: Used in the chemical industry to package granular or powdered chemicals such as fertilizers, pesticides, and other similar products.

Model | VFFS-280C | VFFS-280C-PLUS | VFFS-450C | VFFS-600C |

Film width | Max 300mm | Max 320mm | Max 420mm | Max 580mm |

Bag size | L:30-175/190/210mm W:25-145mm | L:40-240/280/380mm W:25-140mm | L:50-275/295mm W:60-195mm | L:50-380mm W:60-280mm |

Output | 40-90 pcs/min | 30-60 pcs/min | 15-40 pcs/min | 10-30 pcs/min |

Packing range (ml≠g) | 1-20g 10-100g | 20-130g 50-250ml | 100-500g 100/500-1000g | 100-500g 100/500-1000g |

Dimension | 1200x1000x1750 mm | 1200x1000x2000 mm | 1300x1100x2100 mm | 1500x1300x2200 mm |

Total power | 1.5KW | 1.6KW | 2.6KW | 3KW |

Weight | 350kg | 400kg | 450kg | 520kg |

Powder Packaging Machine with Auger System

POWDER PACKAGING MACHINE

A powder packaging machine with an auger system is a type of vertical form fill seal (VFFS) machine that is used to package powdered products. The machine utilizes an auger dosing system to measure and dispense the required amount of powder into the pouch or sachet. The VFFS model refers to the vertical forming, filling, and sealing of the pouch or sachet.

The powder packaging machine with an auger system typically consists of a hopper for storing the powder, an auger screw for measuring and dispensing the powder, a filling tube for transferring the powder to the pouch, and a sealing mechanism for sealing the pouch.

packaging machine for powder

Accurate dosing: The auger system is designed to provide precise dosing of the powder to ensure product quality and consistency.

High-speed production: The machine can package several products simultaneously, increasing production speed and efficiency.

Operator safety: The machines are equipped with safety features, such as safety guards and emergency stops, to protect the operator during operation.

High-quality construction: The machines are typically constructed with high-quality materials, such as stainless steel, to ensure durability, reliability, and hygiene.

Customizable bag sizes: These machines can be customized to produce a wide range of bag sizes, ranging from small sachets to large pouches, to meet the needs of different products and packaging requirements.

INDUSTRIES AND APPLICATIONS

1.Food industry: Commonly used for packaging powdered products such as spices, seasonings, salt, sugar, flour, and baking mixes.

2.Pharmaceutical industry: For packaging powdered drugs, such as antibiotics, vitamins, and other supplements.

3.Chemical industry: Used for packaging various types of powders, including detergents, fertilizers, and other chemicals.

4.Cosmetics industry: For packaging powdered cosmetics, such as talcum powder, face powders, and other similar products.

Model | VFFS-280A | VFFS-280A-PLUS | VFFS-450A | VFFS-600A |

Film width(mm) | Max 300 | Max 300 | Max 400 | Max 580 |

Bag size(mm) | L:30-175 W:28-140 | L:40-190/240/275 W:20-140 | L:50-280 W:60-195 | L:50-280/380 W:60-280 |

Output(pcs/min) | 30-60 | 30-60 | 15-36 | 10-30 |

Packing range (ml≠g) | 0.3-0.6ml 0.5-3ml 2-10ml 8-20ml 15-90ml 20-100ml 50-200ml | 8-20ml 15-90ml 20-100ml 50-200ml | 50-200ml 100-500ml 200-1000ml | 50-200ml 100-500ml 200-1000ml 500-2000ml |

Power | 1.8KW | 2KW | 2.6KW | 3KW |

Dimension(mm) | 1200x1000x1660 | 1200x1000x1900 | 1200x1100x2000 | 1500x1300x2200 |

Weight | 350kg | 400kg | 450kg | 520kg |

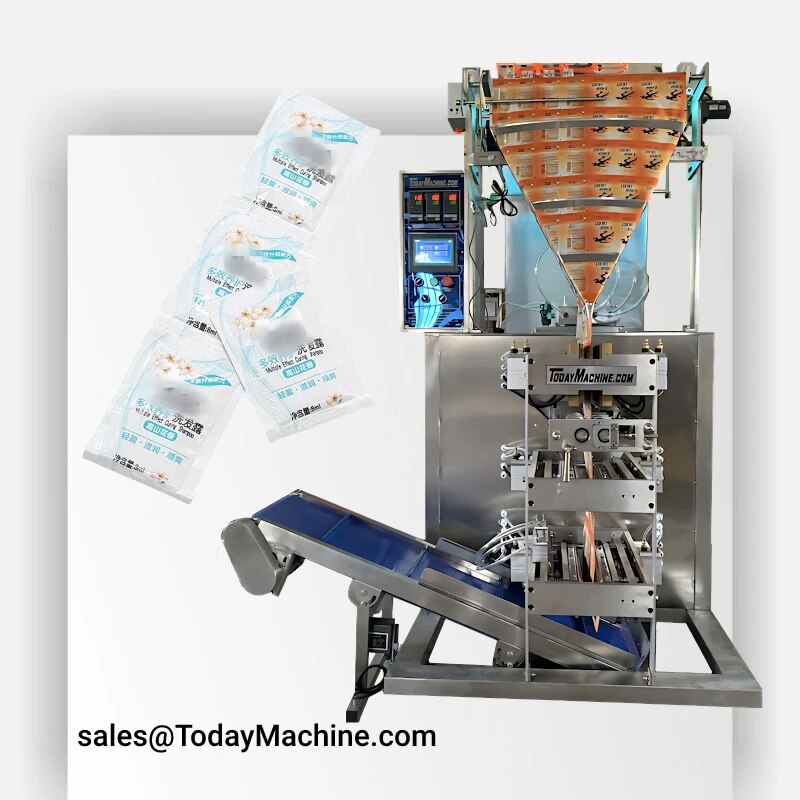

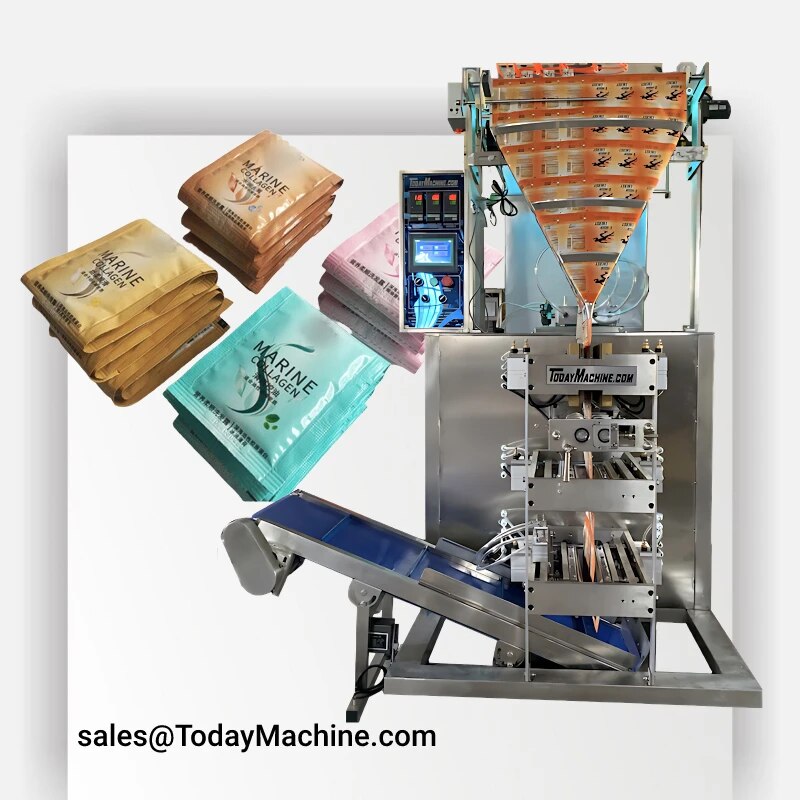

LIQUID PACKING MACHINE

A liquid bag packing machine is a type of packaging machinery used to package liquid products into pre-formed bags. These machines are designed to efficiently and accurately fill and seal bags with liquids such as water, juice, milk, oil, sauce, or other viscous liquids.

The liquid bag packing machine typically consists of a filling system, a sealing system, and a packaging material supply system. The filling system is responsible for measuring and dispensing the liquid product into the bag. The sealing system is responsible for sealing the bag after it is filled. The packaging material supply system provides the pre-formed bags that are filled and sealed.

gel packing machine

Automatic operation: The machine can operate automatically with minimal human intervention, which reduces labor costs and increases production efficiency.

High filling accuracy: The machine uses advanced technology to ensure that the liquid is accurately measured and dispensed into the bag.

Adjustable filling volume: The machine can be adjusted to fill different volumes of liquid, making it versatile for use with different products.

Hygienic design: The machine is designed to ensure that the liquid product is filled and packaged under hygienic conditions, which is important in industries such as food and beverage and pharmaceuticals.

INDUSTRIES AND APPLICATIONS

1.Beverage industry: The machine is widely used in the beverage industry to package products such as water, juice, and milk.

2.Food industry: The machine can be used in the food industry to package products such as cooking oil, sauces, and soups.

3.Chemical industry: The machine is used in the chemical industry to package products such as detergents, solvents, and lubricants.

4.Pharmaceutical industry: The machine is used in the pharmaceutical industry to package liquid medicines and solutions.

5.Cosmetics industry: The machine is used in the cosmetics industry to package products such as lotions, shampoos, and liquid soaps.

TECHNICAL SPECIFICATION

Model | VFFS-280LP-PLUS | VFFS-450LP | VFFS-600LP | |

Film width(mm) | Max 300 | Max 320 | Max 420 | Max 580 |

Bag size (mm) | L:30-175/190/210 W:18-140 | L:40-240/275/380/430 W:20-140 | L:50-275/295 W:60-195 | L:50-380 W:60-280 |

Output | 30-60 pcs/min | 30-60 pcs/min | 15-30 pcs/min | 10-30 pcs/min |

Packing range (ml≠g) | 1–10ml 5-45ml 10-100ml 50-280ml | 25-280ml 50-500ml 200-900ml | 50-280ml 100-550ml 200-900ml 200-1100ml 200-1400ml | 50-280ml 100-550ml 200-900ml 200-1100ml 200-1400ml |

Dimension(mm) | 1150x1000x1760 | 1100x1000x2000 | 1400x1100x2150 | 1500x1300x2300 |

Power | 2KW | 2.2KW | 2.6KW | 3KW |

Weight | 350kg | 400kg | 460kg | 550kg |

Irregular Products Packaging Machine with Bucket conveyor

IRREGULAR PRODUCTS PACKAGING MACHINE

An Irregular Products Packaging Machine with Dump Bucket is a type of packaging equipment that is designed to package irregularly shaped products that cannot be packaged using traditional packaging machines. The machine features a dump bucket, which is used to load the irregularly shaped products into the machine.

The machine is capable of handling a wide range of products, including hardware items, auto parts, plumbing fixtures, and other irregularly shaped products. The packaging process involves the use of a conveyor system to move the products from the dump bucket to the packaging area. The machine uses various types of packaging materials, including bags, pouches, and boxes, depending on the specific needs of the product being packaged.

sachet packaging machine

High-speed packaging: These machines are capable of packaging large volumes of irregularly shaped products in a short amount of time.

Versatility: It can handle a wide range of irregularly shaped products, making them suitable for different types of manufacturing facilities.

Easy to operate: It’s designed to be user-friendly and require minimal training to operate.

Resilient design: It’s typically made of high-quality materials, making them durable and long-lasting.

INDUSTRIES AND APPLICATIONS

1.Hardware manufacturing: Irregular Products Packaging Machines with Dump Buckets are commonly used in hardware manufacturing facilities to package irregularly shaped products such as plumbing fixtures, nuts, bolts, and screws.

2.Automotive industry: The automotive industry uses Irregular Products Packaging Machines with Dump Buckets to package irregularly shaped auto parts such as gears, pulleys, and engine components.

3.Plumbing industry: The plumbing industry uses these machines to package irregularly shaped plumbing fixtures such as valves, faucets, and pipes.

4.Construction industry: The construction industry uses Irregular Products Packaging Machines with Dump Buckets to package irregularly shaped construction materials such as bricks, stones, and concrete blocks.

5.Food industry: These machines are also used in the food industry to package irregularly shaped food products such as fruits, vegetables, and meats.

6.Pharmaceutical industry: The pharmaceutical industry uses Irregular Products Packaging Machines with Dump Buckets to package irregularly shaped medical devices such as syringes, catheters, and surgical instruments.

Model | VFFS-280B | VFFS-280B-PLUS | VFFS-450B | VFFS-600B |

Film width(mm) | Max 300 | Max 300 | Max 420 | Max 580 |

Bag size(mm) | L:40-175/190/210 W:30-140 | L:40-240/280/380 W:30-140 | L:50-275/300 W:60-195 | L:50-380 W:60-280 |

Output | 30-70 pcs/min | 30-60 pcs/min | 15-40 pcs/min | 10-30 pcs/min |

Packing range (ml≠g) | 0-100g | 0-100g | 100-500g | 100-1000g |

Power | 1.8KW | 1.8KW | 2.6KW | 3KW |

Dimension(mm) | 1100x1200x1750 | 1100x1200x2000 | 1200x1100x2100 | 1500x1300x2200 |

Weight | 380kg | 420kg | 450kg | 550kg |

All Posts and Banners,Logos,Images belong to its respective owner & owners.©Copyright 2024.All Rights Reserved!

Disclaimer : This advertisement and the information related to it are provided and maintained by the advertiser. Dkfon.com is not responsible and can not guarantee the accuracy or completeness of this advertisement. Please note that every advertisement for rent or for sale should at a minimum, display the energy performance rating of the property. See our Flats and Housing Posting Rules for more information.

Avoid scams: Signs of fraud: wire transfer, money orders, cashier checks, payment via gift cards, shipping, escrow, "transaction protection", "guarantee". Be safe by dealing locally.

Reviews

There are no reviews yet.