Description

PLEASE NOTE:

1.The price only for reference, the specific cost based on your requirements and the destination port, please contact us for more product details and quotations

2.We ship you by sea !!!

3.Door to door please leave message or whatsapp or email for price !!!

Pictures Of Finished Products Made By Our Machine

The specifications are as follows:

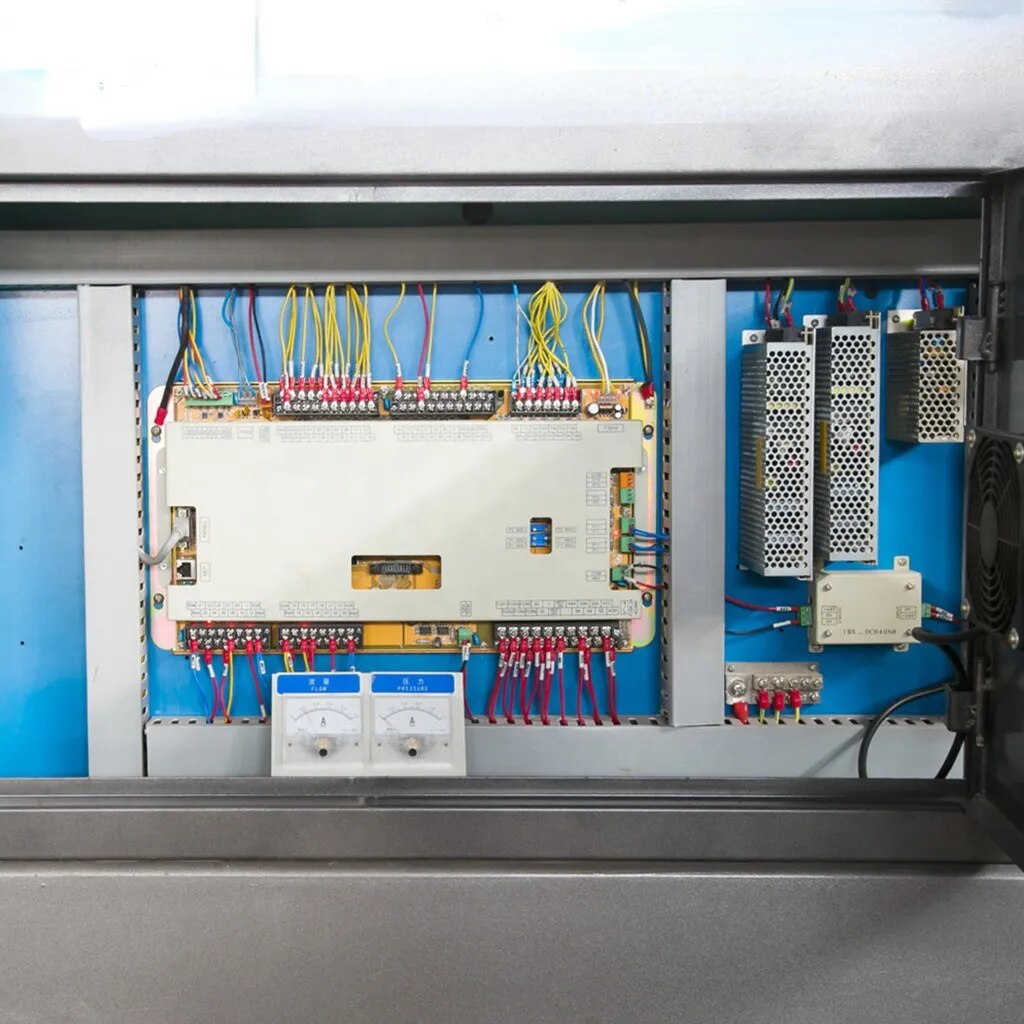

– Imported advanced computer systems, Chinese, English, Russian, Spanish, French, Arabic interface.

– Can save 100 sets of mould parameters.

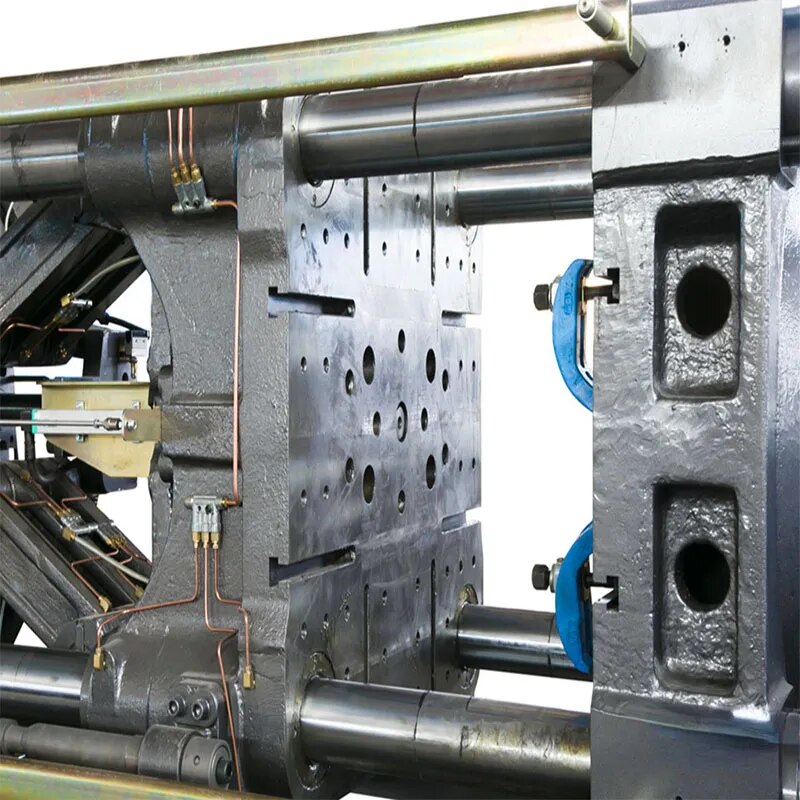

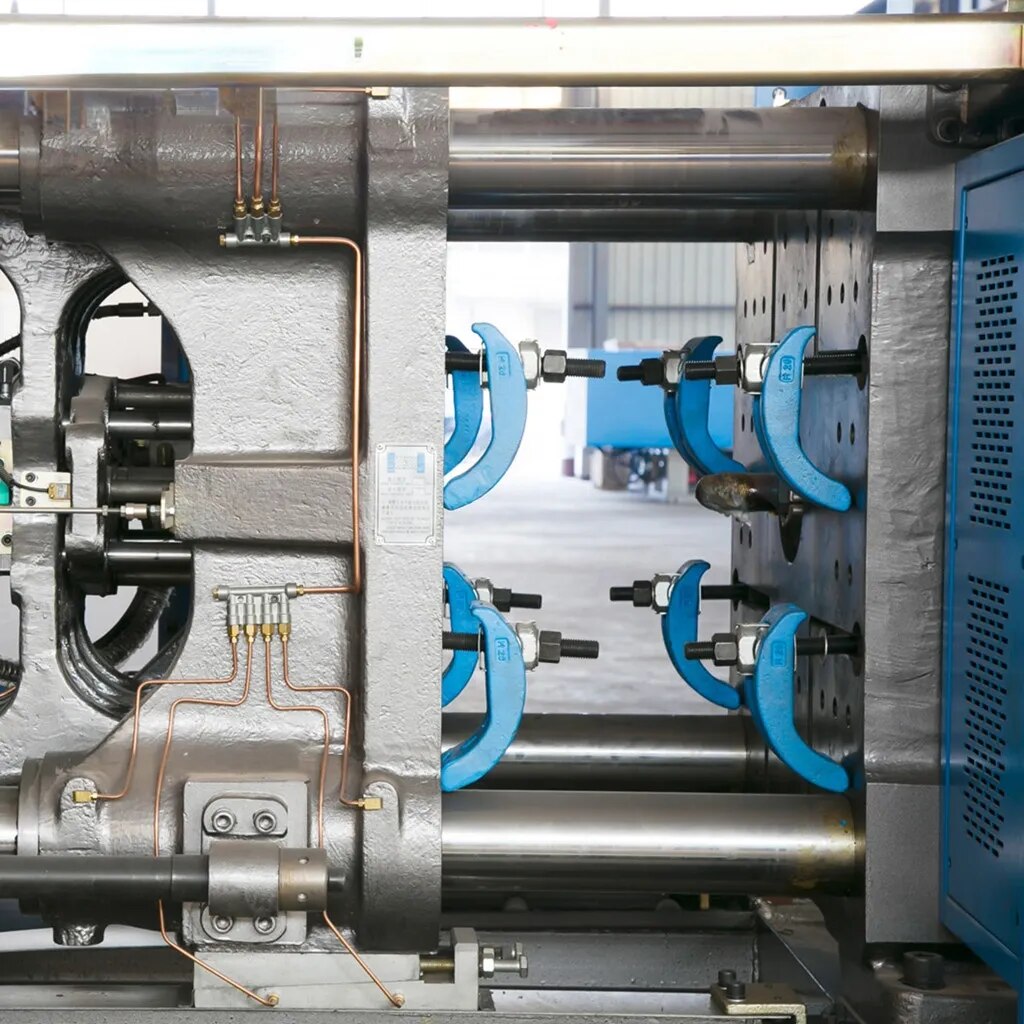

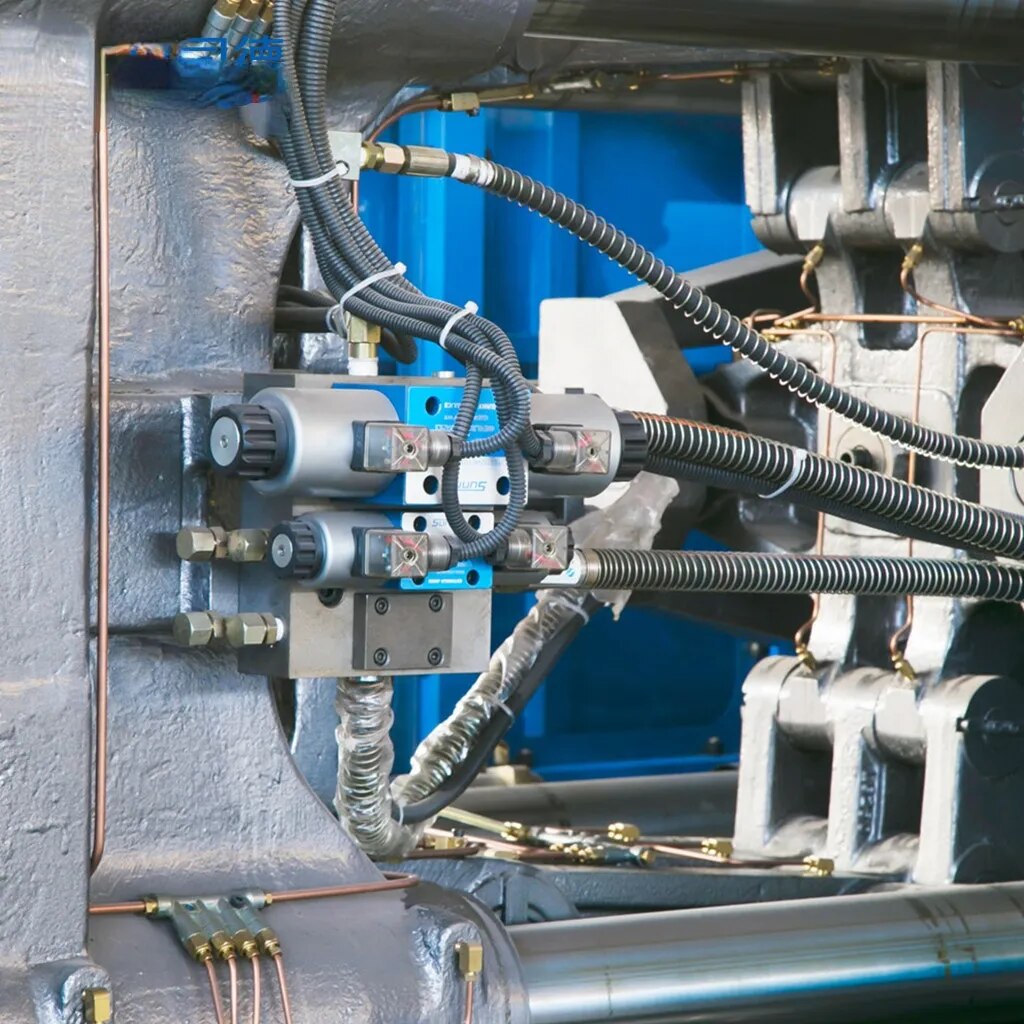

– Advanced clamping structure and injection parts, precision hydraulic system and circuit design.

– Suitable for producing different types of precision small parts.

– A variety of text can be switched.

– Manual, semi-automatic and fully automatic mode.

– Automatic movement monitoring with alarm and fault diagnosis.

– Function of slope setting can set the start and stop of movements, so as ensure the smooth movement.

– Quality:12 month Quality guarantee ,Free spare parts replacement,(NOT include man-made sabotage)

– Service:We provide free advanced training and maintenance in china factory,and 24 hours on-line or phone service if you request we also can provide installation and training abroad,until customer’s satisfaction

– Delivery time: 60 days after advance payment

MODEL | BST-1400A | |||||

INJECTION UNIT | A | B | ||||

Screw Diameter | mm | 36 | 40 | |||

Shot Size(Theoretical) | cm3 | 256 | 280 | |||

Shot Weight | g | 230 | 252 | |||

Injection Pressure | MPa | 176 | 160 | |||

Injection Rate | g/s | 95 | 100 | |||

Screw L/D Ratio | L/D | 23.4 | 22.2 | |||

Screw Speed | r.p.m | 0-190 | ||||

Nozzle Diameter | srmm | 10 | ||||

CLAMPING UNIT | ||||||

Clamp Tonnage | KN | 1400KN | ||||

Toggle Stroke | mm | 365 | ||||

Mould Thickness | mm | 150-420 | ||||

Space Between Tie-bars | mm | 428*386 | ||||

Ejector Stroke | mm | 140 | ||||

Ejector Tonnage | KN | 50 | ||||

Ejector Number | Piece | 5 | ||||

Hole Diameter | mm | 100 | ||||

OTHERS | ||||||

Heat Power | KW | 8.2 | ||||

Max. Pump Pressure | MPa | 16 | ||||

Pump Motor Power | KW | 13 | ||||

Valve Size | mm | 10 | ||||

Machine Dimension | m | 4.8*1.6*1.7 | ||||

Machine Weight | T | 4.2 | ||||

Oil Tank Capacity | L | 220 | ||||

Company Profile

Reviews

There are no reviews yet.