Description

Hot Sale CNC Punching Machine 50t Amada Technology Support Hydraulic Cnc Turret Punch Press Machine Free After-sales Service

Products Description

SERVO CNC TURRET PUNCH PRESS MAX SF SERIES

The new generation of ACCURL turret punch is a low energy, high efficiency turret punch with low environmental and maintenance costs. The ACCURL can be configured in 22 or 33 ton options. The ACCURL was designed with a thick turret to ensure longevity of the machine and its tools and to minimize tool deflection.ACCURL performs full punches, hovering, marking and forming operations. The SF model can be upgraded with our Ultra Package which can decrease part processing times by up to 40%.

The ACCURL comes standard with the following features:

Automatic Tool and Linear Components Lubrication System

Pneumatic Ball Transfer and Brush Table for ease of loading/unloading

Vacuum Assist System for slug removal

32 Stations 2 Auto indexing stations

One Mirror-Type Safety System to guard entire work envelope

Man-Sensors on moving tables

Sheet Jam Protectors to detect warped material

Sheet-gripper sensors to detect loose material

Pneumatic Ball Transfer and Brush Table for ease of loading/unloading

Vacuum Assist System for slug removal

32 Stations 2 Auto indexing stations

One Mirror-Type Safety System to guard entire work envelope

Man-Sensors on moving tables

Sheet Jam Protectors to detect warped material

Sheet-gripper sensors to detect loose material

SERVO DRIVE SYSTEM

The punch servo utilizes a direct drive gearbox that supplies power and speed. This servo allows the user to steplessly adjust the punch stroke and accommodate any pressure curve requirements.

The AC punch servo motor can be programmed for various applications.

1. High speed applications.

2. Low noise applications.

3. Forming applications.

1. High speed applications.

2. Low noise applications.

3. Forming applications.

SOLID FRAM E STRUCTURE

The ACCURL turret punch utilizes an O-frame structure for rigidity and reliability throughout the life cycle of the machine.

QUALITY ENBINEERINS

All frame configurations are field tested and engineered to last using FEA.

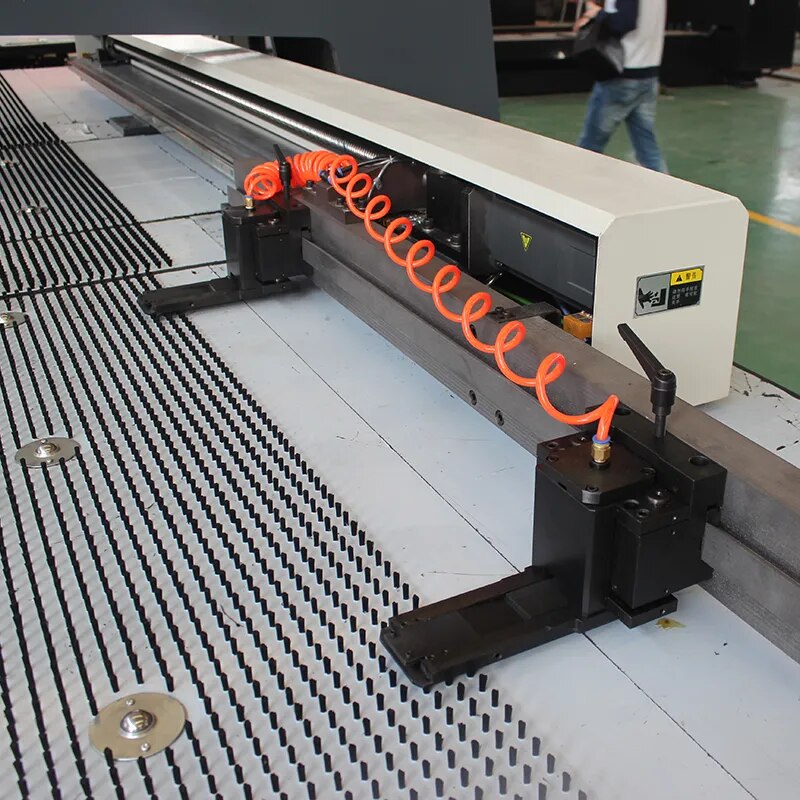

MIXED BALL AND BRUSH TABLE

The standard configuration features a mixed ball and brush table that comes with an

integrated pneumatic ball transfer table to ease loading and unloading.

integrated pneumatic ball transfer table to ease loading and unloading.

SHEET JAM PROTECTORS

Sheet Jam Protectors automatically detects deformed or buckled sheets and automatically

stops the machine when triggered.

stops the machine when triggered.

DROP CHUTE & CONVEYOR

The part Drop Chute and Conveyor options allow processing and sorting to be automated and simplified.

AUTOMATIC CLAMP POSITIONING

Automatic Clamp Positioning reduces set up time and errors, and provides machine run time flexibility and productivity.

MAXIMUM CONTROL

The ACCURL turret punch comes with a FANUC Oi-PD LCD mounted controller. The setup includes an ACCURL Operator panel and FANUC MDI panel.

The FANUC controller allows for precise and reliable machine control, as well as providing a way to monitor secondary systems and keep track of maintenance tasks.

CAD/C AM NESTING SOFT WARE

The G-code for the Oi-PD controller can be generated from nesting software. The operator may nest multiple parts, maximize sheet utilization and streamline their workflow to ensure their turret punch is working in peak condition.

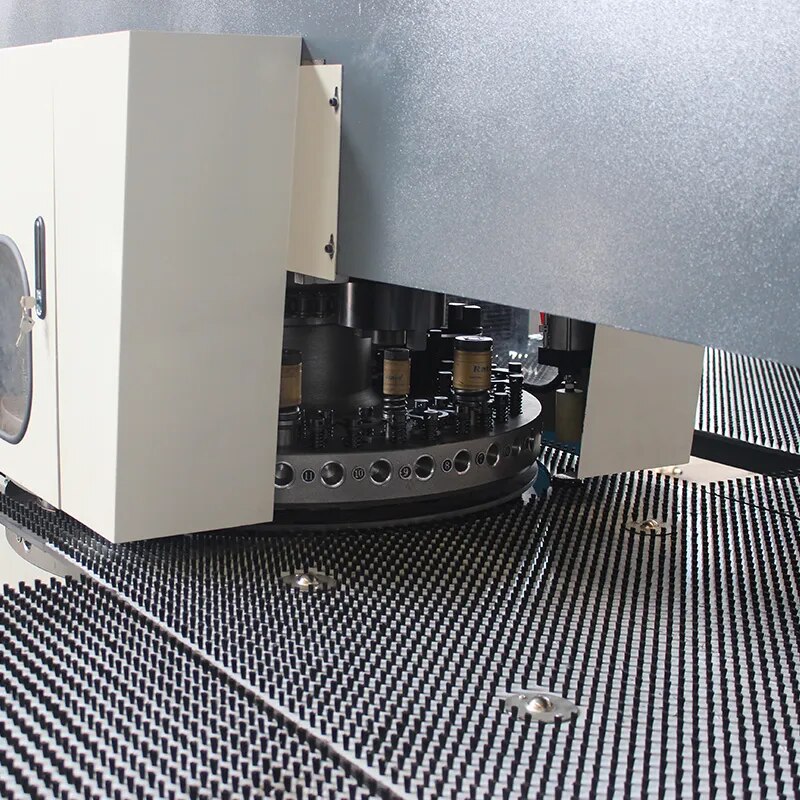

THICK TURRET TOOLING

The ACCURL is compatible with thick turret tooling. The wide variety of specialty tools combined with the programmable ram means the ACCURL can deliver for any application.

The D-station also is configurable with multi-tools with multiple configurations of both A(0.5″) and B (1.25″).

Reduce additional operations by utlilizing ACCURL’s support of tapping and other specialty tooling.

ACCURL SPECIFICATION

|

Item |

Unit |

MAX-SF-30T |

MAX-SF-50T | |

|

Punching Capacity |

Ton |

30 |

50 | |

|

X Traverse Length |

mm |

2500±10 |

2500±10 | |

|

Y Traverse Length |

mm |

1250±10 |

1250±10 | |

|

Max Sheet Size |

1250×5000 |

1250×5000 | ||

|

Max Sheet Thickness |

mm |

6.35 |

8.35 | |

|

Max Sheet Weight |

kg |

110 |

160 | |

|

X Axis Traverse Speed |

m/min |

120 |

100 | |

|

Y Axis Traverse Speed |

m/min |

105 |

80 | |

|

Max Traverse Speed |

m/min |

128 |

105 | |

|

Punching Speed at 25mm Pitch |

Hist/min |

450 |

380 | |

|

Nibbling Speed |

Hist/min |

1200 |

1050 | |

|

Tools Type |

|

Thick Turret | | |

|

Max Punching Diameter |

mm |

88.9 | | |

|

Number of Tool Stations |

|

32 / 42 / 52 | | |

|

Number of Auto Index Stations |

Pcs(type) |

4(2B+2C) / 3(2B+1C) / 2(1B+1C) | | |

|

Turret Rotating Speed |

rpm |

33 |

33 | |

|

Auto Index Rotationg Speed |

rpm |

100 |

100 | |

|

Ram Stroke Distance |

mm |

0~31 |

0~31 | |

|

Working Tables Size |

|

Brush + Supporting Ball Set | | |

|

Number of Sheet Clamps |

Pcs |

3 |

3 | |

|

Air Supply |

NL/min |

250 |

250 | |

|

Air Pressure |

bar |

6 |

6 | |

|

Size of Control Cabinet |

mm |

1350x700x2185 | | |

|

CNC Controller |

|

FANUC Oi-PD | | |

|

Number of Controllable Axes |

Axis |

4 | | |

|

RAM Memory |

KB |

512 | | |

|

Serial Interface |

|

RS232/RJ45/PCMCIA | | |

|

Punching Precision |

mm |

±0.1 | | |

|

Machine Dimension (L x W x H) |

mm |

5940x5220x2420 |

5940x5220x2420 | |

|

Net Weight (approx.) |

kgf |

13,500 |

15,800 | |

Company Profile

WHY CHOOSE ACCURL ?

ACCURL is a famous manufacturer of metal sheet equipments in world market. Its Brand ¡°Accurl¡± has been leading brand for many years in the field of international metal sheet equipments. Our group devote ourselves to product development, production and sales. Our main products are: CNC Press Brake, Shears, Hydraulic press, Laser Cutter and CNC rolling machine these sheet metal processing equipments.we are using advanced technology from German, Japan, and Italy.we can produce large Hydraulic Press and Press Brake more than 16000 ton & 16m.we are with professional R&D team, and we have World-class design and manufacturing capabilities.

WE GOT

5 STARS

RATING!

5 STARS

RATING!

Exhibition

Product packaging

We are currently reviewing our product packaging from the angles of waste-reduction and resource-saving. We are also working on improving transportation efficiency from the design phase of product development.

1.Our wooden case is after fumigation treatment. Needn’t timber inspection, saving shipping time. 2.All the spare parts of the machine were covered by the some soft materials mainly using pearl wool.

3.The outmost is wooden case with fixed formwork. 4.The bottom of the wooden case has firm iron jack, convenient to handing and transport.

Our Serives

The use of an interferometer records the machines X and Y axis movement during cutting to ensure accuracy.

Adjustments are made to ensure machine is precisely tuned before shipment.

Adjustments are made to ensure machine is precisely tuned before shipment.

A Marble test is performed to measure the X and Y axis, calculating any necessary adjustments to ensure perfect level and alignment along length of machine.

A collimator is run along the full length of the guide rail, testing for

straightness. Adjustments are made as required to ensure linear accurae linear accuracy.

FAQ

1.Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

2.What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment.

The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

3.What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal:30% deposit in advance, 70% balance against the copy of B/L.

4.What is the product warranty?

We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone’s satisfaction.

5.Do you guarantee safe and secure delivery of products?

Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.

6.How about the shipping fees?

The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way. By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of amount, weight and way. Please contact us for further information.

The product is super heavy, please contact customer service for detailed weight before purchase

Reviews

There are no reviews yet.