Description

PLEASE NOTE:

1.The price only for reference, the specific cost based on your requirements and the destination port, please contact us for more product details and quotations

2.We ship you by sea !!!

3.Door to door please leave message or whatsapp or email for price !!!

1.The price only for reference, the specific cost based on your requirements and the destination port, please contact us for more product details and quotations

2.We ship you by sea !!!

3.Door to door please leave message or whatsapp or email for price !!!

How To Build A PS Foam Food Container Manufacturing Plant ?

A foam food container is a form of disposable food packaging for various foods and beverages, such as processed instant noodles, raw meat from supermarkets, ice cream from ice cream parlors, cooked food from delicatessens or food stalls, or beverages like "coffee to go".

They are also commonly used to serve takeout food from restaurants, and are also available by request for diners

who wish to take home the remainder of their meal. The foam is a good thermal insulator, making the container easy to carry as well as keeping the food at the temperature it had when filled into the container, whether hot or cold.

They are also commonly used to serve takeout food from restaurants, and are also available by request for diners

who wish to take home the remainder of their meal. The foam is a good thermal insulator, making the container easy to carry as well as keeping the food at the temperature it had when filled into the container, whether hot or cold.

Product Paramenters

Parameter |

Unit |

Model | ||||

YG-1100 |

YG-1250 |

YG-1400 | ||||

Forming area |

mm 2 |

1100×1100 |

1100×1250 |

1100×1450 | ||

Cutting height |

mm |

160 |

160 |

160 | ||

Productivity |

s/cut |

3-4 |

3-4 |

3-4 | ||

Dimension |

m |

19x6x3 |

21x6x3 |

24x6x3 | ||

Power |

KW |

150 |

160 |

180 | ||

Power supply |

V/HZ |

380/400/415V, 50/60HZ, 3PH | ||||

Products Description

Introduction

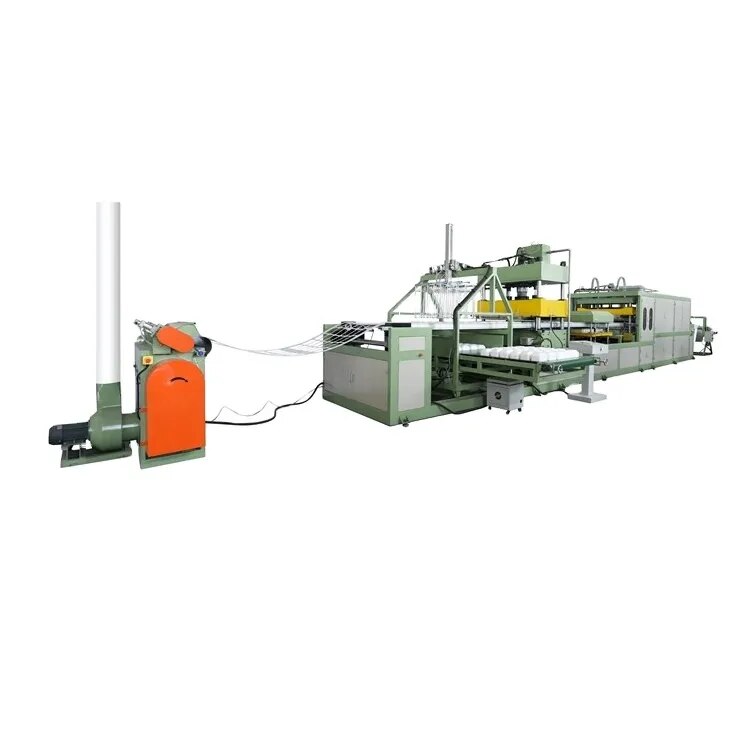

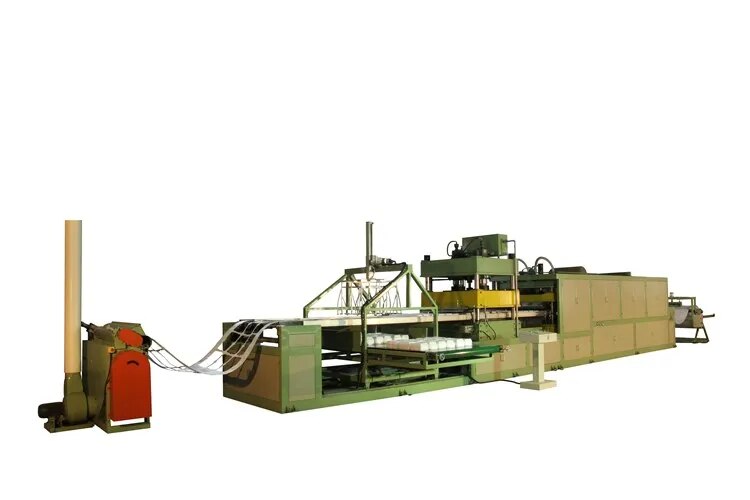

This PS foam sheet production line adopts the double-machine tandem high-foaming sheet production process. The PS foamed sheet produced is a new type of packaging material, which not only has good heat insulation and cushioning properties, but also has a pearl-like appearance and color. PS foam fast food lunch box container tray plate making forming machine is mainly used in the manufacture of disposable tableware, and can be made into various types of food containers such as lunch boxes, trays, dishes, etc. It can also be used for the production of advertising boards and the packaging of industrial products. It has the characteristics of high output, stable performance, high degree of automation and high product quality.

1. PS Foam Sheet Extrusion Line

PS Foam Sheet Extrusion Line adopts Gentian type double-stage series high foam technology.

The raw material is general polystyrene granule. In the extruding process, vesicant is injected at high pressure.

After extruding, foaming cooling, shaping and hauling off, it is winding to finished PS foam sheet rolls.

After vacuum forming system, the finished PS foaming sheet can be made into variety of packaging vessels such as fast food box, aquatic plate, supermarket tray, cake tray ,KT board, instant noodle bowl, foam tray etc.

It is widely used in the packing of food, fruit advertising ,industrial products and so on. This equipment adopts high speed non-stop hydraulic filter changer and PLC controller, advantages as advanced structure, stable performance, easy operation and high quality.

2. Double Worktables Fully Automatic Vacuum Forming Machine

Double Worktables Fully Automatic Vacuum Forming Machine integrate forming ,cutting ,robot arm grab at the same time ,also the foam products could come out autimatically. It is vacuum forming as well as press forming and synthetically forming.It can be used for processing all kinds of plastic sheet.It adopts PLC controller and touch screen to control the working programmer.It is easy to operate and features high degree of automation.

3.

Recycling Granulator

Recycling Granulator

Recycling Machine is machine is mainly used to recycle the PS foam polyethylene products. It is the ideal equipment to recycle the

waste materials.

waste materials.

At present ,it is the ideal energy-saving equipment to let the material circulation and reduce the waste.

Company Profile

FAQ

1. Is Polystyrene Recyclable? YES. Polystyrene is 100% recyclable 2. We are new in this field, how can we set up a factory? Dear, don’t worry, we did many turn-key project from 2008 until now, we have enough experience for helping you setting up a new factory, and we can provide the raw material (GPPS, HIPS, mast batch and so on), formulations, machines, and your factory design & layout, and we will arrange our engineers go to your factory for installation and training, you have Melite Team, take it easy, we are at your services all the time. 3. What should we prepare except material? You should prepare workshop, water line, electric line, compress air. We can supply workshop layout drawing according to your workshop. 4. Can you customize machines as per our requirement? It is no problem, we can make machine according to your requirement, such as part brand, machine color, labels, moulds, etc. 5. How many countries have your machine been installed? In Africa, we have machines work in Egypt, Nigeria, The Republic of South Africa, Benin, and Mozambique and so on. With our customers support, we were successfully set up more than 60 lines all over the world. 6. How does you after-sale service work if the product got damaged? In the guarantee time 12 months, our general after-sale service is changing the damaged parts for the customers, but if the damage can be repaired by slight cost, we would wait for the customer’s bill for the fix cost and refund this part of cost. (note: vulnerable part do not include)

7. Will you conduct training for our staff here? Yes, we will arrange our professional engineers to install and test machine and train the buyer’s engineers. 8. Machine adjustment and installation? We can send technicians go to customers’ country for machine adjustment and installation.

Reviews

There are no reviews yet.